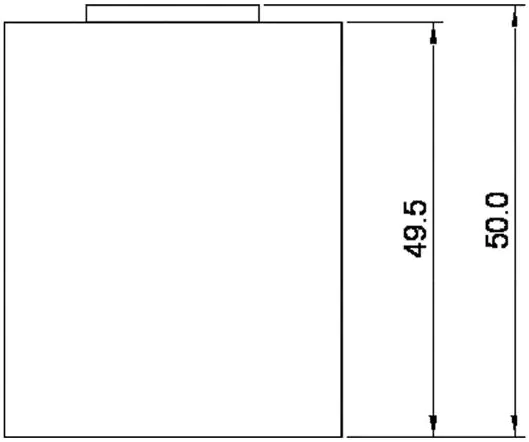

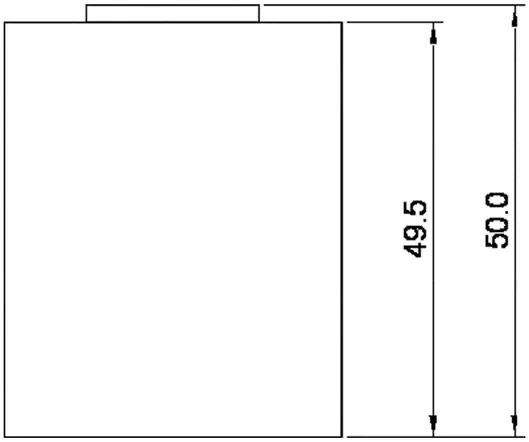

Zero position adjustment tool

Material: hardened steel, with spring-loaded measuring surface.

Application: for determining the position of machined surfaces or tool lengths in the Z direction on lathes and milling machines. The jig is mounted on the workpiece. By means of the machine spindle, a cutting tool, e.g. a milling cutter, is pushed to the measuring surface until the pointer of the measuring clock indicates the zero position. The distance between the cutting tool and the workpiece is then exactly 50 mm, so that the blades are not damaged during the measurement.

Scope of delivery: zero position setting instrument with timer.