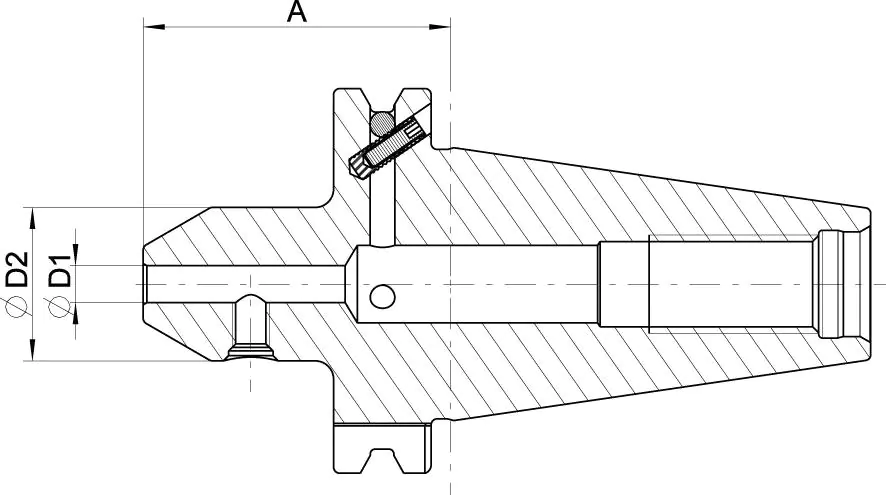

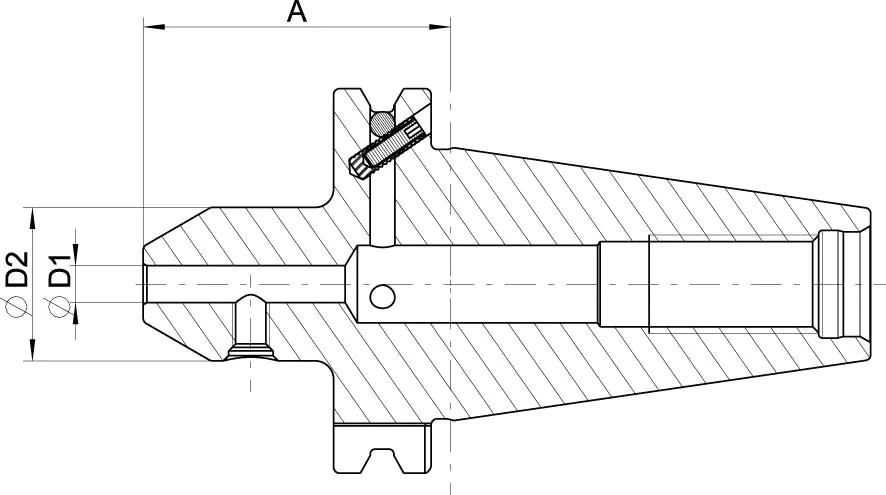

Weldon lampholder, DIN 69871, SK 40, balancing quality G2,5 22000 min-1

Made of: alloyed steel for carburizing, core tensile strength approx. 950 N/mm2, minimum hardening depth 0.5 mm. Cone according to DIN 254. All functional surfaces after finishing , guaranteed quality thanks to double 100% control.

Cone angle tolerance: AT3

Hole tolerance: H5

Hardness after quenching: 60 –2 HRC

Application: for clamping cutters with cylindrical shank and side carrier surface according to DIN 1835-B and DIN 6535-HB.

Scope of delivery: Weldon clamping holder with mounting screw.

Radial run-out tolerance: < 0.003 mm.

Hardness after hardening: 60 –2 HRC.

All functional surfaces machined