V-COIL thread repair kit

Drilling: drill damaged threads with ordinary twist drills. No drilling is required for spark plug threads; In this case, a drilling and notching tool is used. Please note that larger holes are required when kneading the thread.

Check: check that the tap and threaded pins match in thread and stroke.

Thread: use a special V-COIL tap to cut the thread into the drilled hole. It is recommended to use oil for machining.

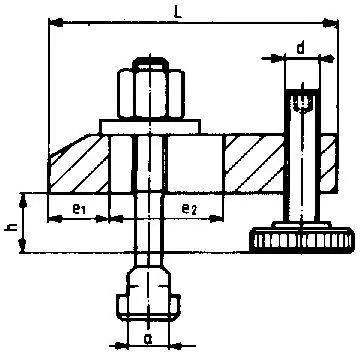

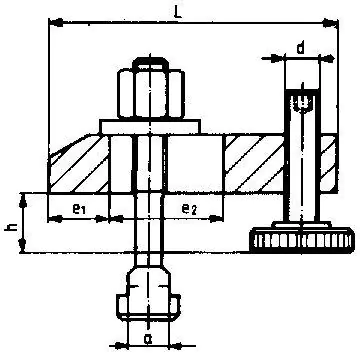

Thread insert mounting: Attach the insert to the tool, making sure the pick-up pins are placed in the tap grooves, then adjust using the adjustable ring. Screw the insert in accordance with the thread coil under light pressure.

Do not turn opposite to the direction of screwing, the journal may break.

Pinch fracture: after introduction, remove the tool and remove the spigot with the collector breaker. For larger dimensions and with spark plug threads, the pivot is pulled out with pliers with narrowed ends. Thanks to tight and accurate tolerances and the forming process, a thread is created at the end of these operations, which is often better and stronger than the original thread.

Application: thread reinforcement from materials with limited shear strength, e.g. aluminum and magnesium alloys, application in machine manufacturing, automotive, electrotechnical, medical and aerospace industries, repair of damaged or worn threads, reuse of defective product.

Supplied: in plastic cassette, screwdriver, twist drill in thread hole dimensions, tap and thread inserts (1.5 x D).