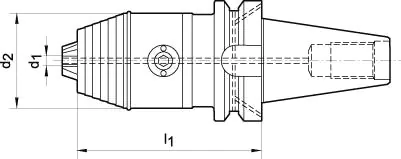

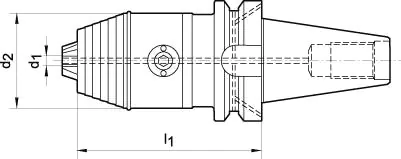

CNC precision chuck, right and left wing, JIS B 6339, A shape, BT 50

Made of: alloyed steel for carburizing, core tensile strength approx. 950 N/mm2, minimum hardening depth 0.5 mm. Cone acc. to DIN 254. Hardness after hardening: 58 ± 2 HRC. Short design with central coolant supply, handle and mandrel from one part. The clamping (using a hex wrench) allows a significant increase in clamping force compared to traditional chucks. At the same time, the handle is protected against loosening at left turns and fast deceleration from high rotational speeds.

Cone angle tolerance: AT3

Cone surface roughness: Ra < 0,001 mm

Radial run-out tolerance: 0.02 mm

Balance Quality: G6.3 22000 min-1

Application: for fixing tools with cylindrical shank and internal cooling.

Scope of delivery: short CNC chuck with sealing washer for drills with a cooling channel with a diameter of 3-6 mm.