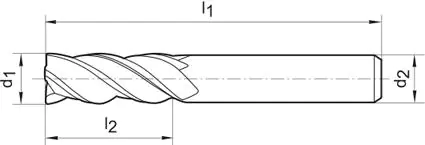

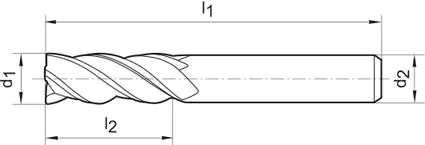

Mandrel cutter, solid carbide

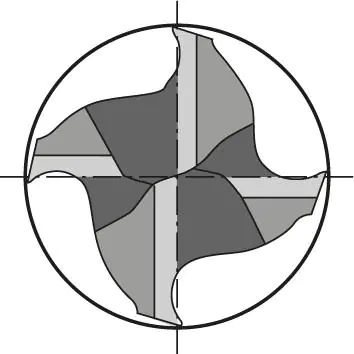

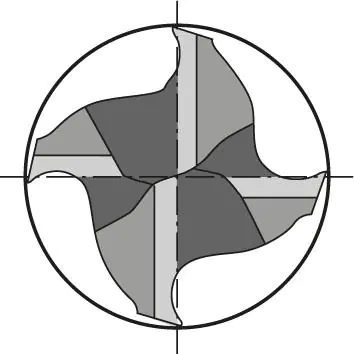

Material: ultrafine grain cemented carbide, type N, DIN 6527, 35°/38°, with central blade.

Cutting speed approx. 50 % higher than uncoated tools. Dry processing possible. Air cooling recommended.

Application: for circumferential milling and universal machining. For milling to a maximum depth of 2 x D. Also for edge milling and finishing. For roughing and finishing milling and grooving as well as for grooving milling. Extremely quiet operation thanks to the uneven 35°/38° groove line to achieve good surface quality workpiece. Compared to traditional tools, significantly longer service life and maximum stability during machining. In addition, up to 60 % higher feed rates can be achieved.