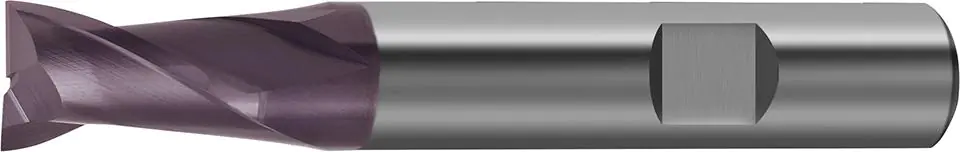

Mandrel cutter, solid carbide

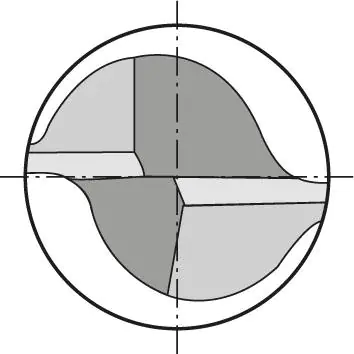

Execution: with center blade, suitable for drilling.

Application: for milling keyways and keyways P9 and for universal machining

Cutting speed approx. 50 % higher than uncoated tools. Dry processing possible.

| Aluminium > 8% silicon: | 120 |

|---|---|

| Cast iron gg/gts: | 120 |

| Copper alloys: | 80 |

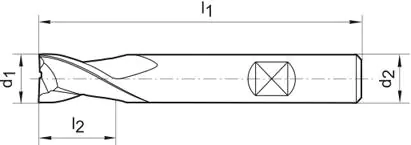

| Cutting part length l2: | 7 mm |

| Diameter d1 = h 10: | 6 mm |

| Ggg cast iron: | 96 |

| Hardened steel < 55 hrc: | 30 |

| Inox austenite.: | 40 |

| Inox duplex: | 32 |

| Inox ferrite./martenz.: | 50 |

| Shank diameter d2 = h6: | 6 mm |

| Steel < 1000 n/mm2: | 92 |

| Steel < 1000 n/mm2 fz: | 0.024 mm/rev. |

| Steel < 1400 n/mm2: | 74 |

| Steel < 700 n/mm2: | 115 |

| Titanium > 850 n/mm2: | 40 |

| Total length l1: | 54 mm |

Mandrel cutter, solid carbide

Execution: with center blade, suitable for drilling.

Application: for milling keyways and keyways P9 and for universal machining

Cutting speed approx. 50 % higher than uncoated tools. Dry processing possible.

Despite our best efforts, we cannot guarantee that the published technical data and photos do not contain inaccuracies or errors, which, however, cannot be a basis for claims.