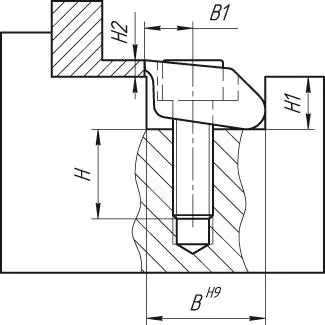

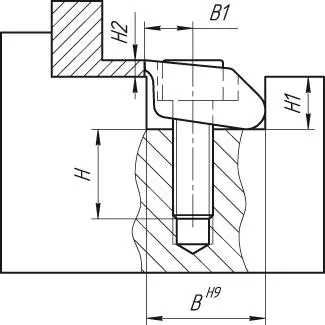

Pitbull® clamping in tool steel, with knife edge

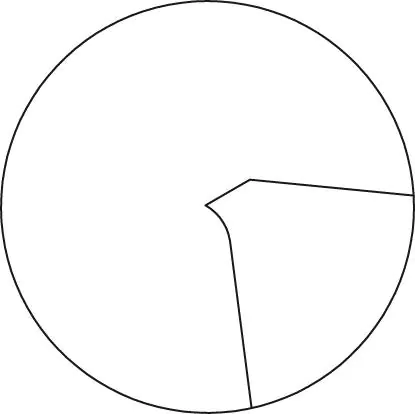

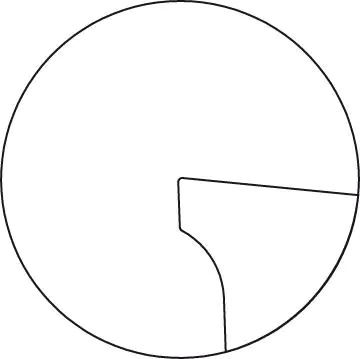

Universal pressure system for pressing workpieces of various shapes and forms, square, inclined, concave or convex.

Design: the special feature of these clamps is a steel screw (with a strength of 10.9) with an eccentric head. Eccentricity causes a pressure movement with a very high clamping force. The clamping element is a brass hexagonal plate.

Application: with the help of thrust pins and 1 or 2 mounting screws, each element can be fixed in the most diverse forms. The low construction height enables trouble-free machining of the workpiece surface. In this way, it is not necessary to take into account the position of the clamping feet when programming the CNC. In addition, the small design dimensions allow ergonomic multiple mounting. The mounting clamps can also be used as stops.

Design : Pitbull calipers can be supplied in 3 versions:

– tool steel, with a knife edge for untreated parts (casting, forging, cut element)

– tool steel, with blunt edge for general applications

– brass, with a blunt edge to avoid damage to the fixed surface

Application: simple and ingenious. The back side of the clamp rests against the mounting plate, tightening with a screw (DIN 912) pulls the clamping edge forward. In this way, an absolute pressing effect is achieved, allowing for precise processing of a wide range of details. Besides, it is excellent for multiple mounting. The small design dimensions allow multi-sided machining, without interfering edges.

Kit contents: clamping clamp with screw (DIN 912), clamp and O-ring.