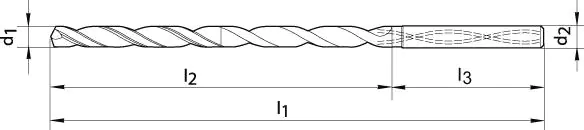

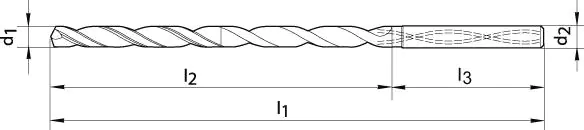

Deep hole drill, 20 x D

The course of the RT 100 T operation:

• Milling the surface at right angles to the axis of the drill during the hole.

• Design of cylindrical pilot hole (tolerance F9) with a minimum depth of 1 x D.

• Input to the pilot hole at approx. 300 rpm at f = 500 mm/min.

• Coolant pressure and rotational speed setting.

• Continuous drilling to full depth without chip evacuation cycle.

• For through holes with a diagonal outlet hole, the feed rate should be reduced to 40 % approx. 1 mm before puncturing.

• When the drilling depth is reached, turn off the rotational speed and coolant supply, exit from the drilled hole at high speed.

• Conventional coolant lubrication at a pressure of at least 40 bar.

Note: drills can be sharpened repeatedly.

All drills for deep holes when entering the material must be guided.

Drills cannot work freely in the working space of the machine at full speed.

Execution: right-handed. Special groove shape with double chamfer and special grinding. Spiral grooves supplying coolant. Lateral approach angle 30°, core thickness greater than normal, no convergence. Drill with very good self-centering properties.

Application: for holes with very tight diameter tolerances and very high surface quality. Designed for drilling very deep holes max. 20 x D, with high cutting speeds. Used in particular for short-chip materials such as cast steel, grey cast iron, improved grey cast iron, malleable and pearlite cast iron and aluminium alloys with a high silicon content.