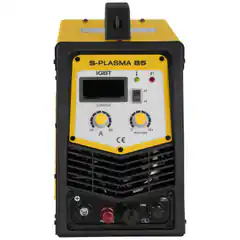

Name of manufacturer: S-PLASMA 85CNC

The plasma cutter of the German welding market leader STAMOS GERMANY is able to achieve a maximum cutting current of 85 A. This will enable efficient processing of materials such as steel, nickel, aluminum, copper and other electrically conductive metals. Thanks to this, the equipment will be used in many industries requiring precisely cut metal elements.

The device uses advanced IGBT technology . It uses special bipolar transistors with an isolated gate that ensure reliability. Fast parameter switching and low short-circuit risk is guaranteed by the three-phase semiconductor element. IGBT also affects the small size of the device, while maintaining high parameters.

Product features:

- - Functionality - for cutting steel and other electrically conductive metals (titanium, copper, brass , etc.)

- - Versatility - a special socket allows you to connect the cutter to the CNC plotter

- - Efficiency - modern IGBT technology and non-contact arc ignition ensure smooth and stable operation,

- - Simple operation - large knobs and switches allow you to precisely determine the operating parameters without having to remove the gloves,

- - Readability - LED display presents current intensity even in dark rooms, and LEDs inform about the drop in air pressure,

- - Easy transport - comfortable handles, small size and weight allow you to easily move the cutter as needed,

- - Convenience - long 5 and 4-meter cables guarantee freedom of movement during cutting and facilitate work in hard-to-reach places,

- - Safety - built-in fan to guarantee heat dissipation,

- - Model - S-PLASMA 85CNC

- - Catalogue number - 2079

- - Article status - New

- - Voltage/frequency - 400 V (3 phases)/50 Hz

- - Function - Plasma cutting

- - Input rated current - 13,2 A

- - Maximum input current - 18.6 A

- - Input rated power - 13,2 kVA

- - Maximum input power - 18,6 kVA

- - No-load voltage - 280 V

- - Cutting current - 20–85 A

- - Duty cycle - 60%

- - Duty cycle cutting current 60% - 85 A

- - Duty cycle cutting current 100% - 65.8 A

- - Final gas outflow time - 5, 10, 60 s

- - Ventilation - Windmills

- - Handle cooling - Gas

- - Grounding cable length - 3 m

- - Cutting cable length - 5 m

- - Air hose length - 4 m

- - Power cord length - 3.8 m

- - Maximum thickness of cut material - 27 mm

- - Cutting width - 1,2 mm

- - Required air flow - 175 l/min

- - Air pressure - 5,5 bar

- - Insulation class - F

- - IP rating - IP21s

- - Compliance with standards - EN 60974-1 / EN 60974-10

- - Declaration of conformity - CE

- - Dimensions (LxWxH) - 56 x 22 x 37 cm

- - Weight - 20.1 kg

- - Shipping dimensions (LxWxH) - 65,5 x 37,5 x 45 cm

- - Shipping weight - 26,5 kg

- Plasma cutting - thanks to the current of up to 85 A, the device will easily cut metals such as iron, stainless steel, cast iron, copper or aluminum. The air pressure is infinitely adjustable, allowing precise control of the plasma jet. Not burning the material, a small amount of distortion and a smooth cutting gap are some of the advantages of using the multifunctional Stamos Germany.

- - 2T/4T, i.e. a two-bar and a four-stroke . When using the first one, pressing the button will initiate the cut, and releasing it interrupts this process. In the case of a four-stroke, the user does not have to hold the buttons constantly, because pressing and releasing the button starts or ends the work,

- - Non-contact plasma arc ignition allows you to start cutting without contact with the workpiece, which reduces wear of consumable parts and improves work efficiency,

- - Gas Post-Flow Time, i.e. regulation of gas outflow. Prevents oxidation of the weld,

- - S-PLASMA 85CNC cutter

- - Plasma cutting handle 5 m

- - Grounding wire with 4 m terminal

- - Air hose 4 m

- - Pressure regulator

- -Manometer

- - Cutting chuck components

- - Manual EN